|

|

|

|

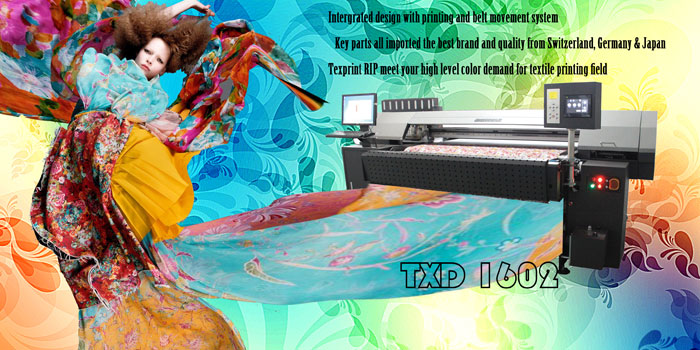

High speed and quality digital printing for cotton, silk, hemp (linen), and rayon.

The TXD1602 features a conveyor belt system to ensure stable feeding of materials, especially for elastic fabric. The concept of this product is high-speed and stable printing.

Substantializing high definition print

Nongranular, high image quality is achieved by variable dot sizes of 1.5pl and 21pl.

High quality print with reliability

A function(eclosion)to reduce banding (stripes in the direction of media feed) during printing is provided.

Fast print speed

Standard mode: 28m2/h (4-color spec)

CISS (Continuous Ink Supply System)

The bulk ink supply system achieves stable unattended printing with 8pc big ink tanks (1.8L) and cartridges (220ml), thus in 4 color mode, a maximum of 4L per color is enabled for long continuous printing.

Operators can also refill the ink tanks even when the printer is at work.

| Feed & take up system

More feeding options available, it can satisfy many different material printing, realize multiple application in textile field.

|

|

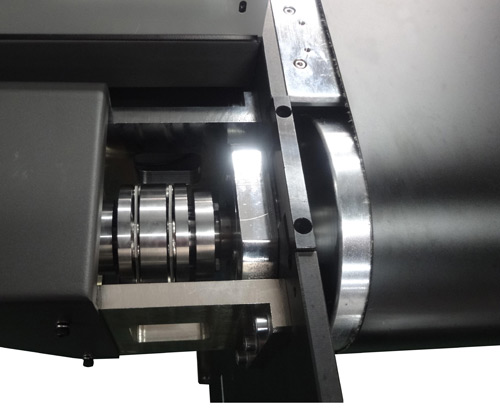

| Stable and precise belt system

Using top quality Swiss Habasit industrial belt with more than 300mm diameter strong accurate steel roller, durable use without deformation; German gearboxes and Japan Panasonic motor for more stable and precise steeping.

|

|

| PLC control system

PLC intelligent control, ensure every auxiliary function of the machine could well coordinately

|

|

| Automatic belt clean and drying

Stained conveyor belt is automatically washed with cold water and then automatically dried with an air blade. By keeping the conveyor belt clean, the media is protected from getting dirty or wet. Piping for feed water & drainage is necessary.

|

|

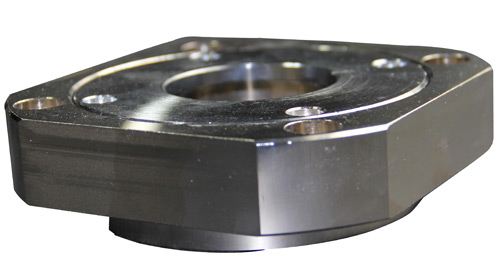

| Integrated unit design

We independently designed this belt printer machine as integrated unit,avoid bad printing and stepping precision of other modified belt machines which are composed by imported main printing part with self designed machine body. |

|

|

In order to guarantee the strong solid machine body with high accuracy, each side we use many solid and precise blocks and aluminum turning parts as the core auxiliary components for the mechanical connection. |

|

| Specialized Textile printing software

Adopt specialized textile printing control system, the perfect wave curve can adapt well to temperature and humidity changes, realize stable printing without break line or head clog. Strong and big dot inkjet make sure that even high up the printhead for thick material, it can print very accurate and without any ink spray. It also highly improves the color gamut under same printing model compared with others.

|

|

| Professional TEXPRINT RIP

Adopt professional TEXPRINT RIP software, achieve real textile 8 color. It has intelligent photocomposing and spot color function, with rich color gamut and perfect color performance. For mass textile production, the printed fabric will have exact same color. 4 or 6 color also avaliable to satisfy client’s demand for different printing quality and material feature.

|

|

Print technology |

Product Model |

TXD1602 |

TXD1604 | |

|

Head |

Drop-on Demand Piezo Epson DX5 head | |||

|

Head quantity |

2 heads |

4 heads | ||

|

Print mode |

Production |

4pass 28m2/h 720*720dpi |

4pass 56m2/h 720*720dpi | |

|

Standard |

6pass 21m2/h 720*1080dpi |

6pass 42m2/h 720*1080dpi | ||

|

High quality |

8pass 17m2/h 720*1440dpi |

8pass 34m2/h 720*1440dpi | ||

|

Ink |

Type |

Reactive、Acid、dispersed ink optional | ||

|

Supply system |

CISS | |||

|

Amount |

4*220ml cartridge, 8*1.8L ink tank | |||

|

Color variation |

4Color(C M Y K)、8color(C M Y K Lk R Bl Or) | |||

|

Media |

Type |

Cotton, Silk, Wool, Viscose, Tencel, Polyester, Nylon | ||

|

Width |

Max. 1600~1800mm | |||

|

Thickness |

Max.8mm | |||

|

Weight |

Max. 80kgs | |||

|

Roll diameter |

Max. 40mm | |||

|

Media heater |

Infrared heating system equipped | |||

|

Media take-up device |

Auto Media feeding&take-up system equipped | |||

|

Belt clean |

Equipped | |||

|

Interface |

USB 2.0 | |||

|

Software |

Texprint 、Photoprint、 maintop | |||

|

Operating System |

Windows XP/ Windows7/Windows8 | |||

|

Operation environment |

Temperature:20~80℃ Humidity: 40%~60% | |||

|

Power specification |

AC22V, 50Hz | |||

|

Packing (dimension/weight) |

3.45*0.95*1.57m/400kgs |

3.45*0.95*1.57m/400kgs | ||