|

|

|

|

Equipped with double rubber rollers, TXR1802 make it possible to print a wide range of fabrics with high printing quality, polyester, flax, cotton, silk, nylon, and sublimation transfer paper all are available.

Specialized Textile printing software

Adopt specialized textile printing control system, the perfect wave curve can adapt well to temperature and humidity changes, realize stable printing without break line or head clog. Strong and big dot inkjet make sure that even high up the printhead for thick material, it can print very accurate and without any ink spray. It also highly improves the color gamut under same printing model compared with others.

Head height adjust

The print-head height adjust device can realize different thickness material print, it can adjust to more than 3.6mm (maximum 10mm) above, together with the new printing control system of accurate and powerful inkjet, it totally solve the normal problem of material scratching.

CISS (Continuous Ink Supply System)

The bulk ink supply system achieves stable unattended printing with 8pc big ink tanks (1.8L) and cartridges (220ml), thus in 4 color mode, a maximum of 4L per color is enabled for long continuous printing.

Operators can also refill the ink tanks even when the printer is at work.

Professional TEXPRINT RIP

Adopt professional TEXPRINT RIP software, achieve real textile 8 color. It has intelligent photocomposing and spot color function, with rich color gamut and perfect color performance. For mass textile production, the printed fabric will have exact same color. 4 or 6 color also avaliable to satisfy client’s demand for different printing quality and material feature.

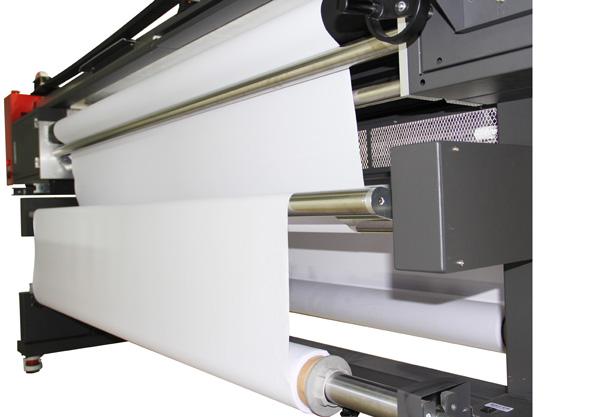

| Double rubber-roll as core driving source

The front and back synchronic rubber-roller as driving source, tight and drive the media stably plus the accurate transmit of Panasonic motor, it can move different heavy and thickness fabric without overlap or gap, thus it can apply on various material such as thin chiffon, thick blanket, stretchable polyester or napped material even is available. And it completely avoid the problem of traditional pinch roll which hook media, leave press track, lose media movement balance, limited by media type .

|

|

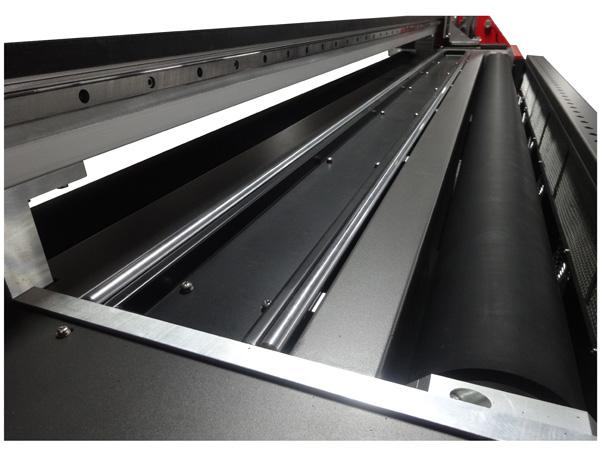

| Printing flatbed

The printing flatbed use Aluminum block and double circular steel pipe, guarantee the platform deviation within 0.1mm, improve the inkjet accuracy,make sure the whole printed image will be same vivid color.

|

|

| Automatic Feeding and Take-up system with heavy duty media load

The AMF system ensures stable feed/take-up of both thick and thin rolled media by automatic tension and speed adjust, there is no need to constantly monitor the printer during high volume printing.

|

|

| Media preheat and Fast drying device

The front and back integrated drying device help pre-heating the material and accelerate the ink drying time by heating the media after printing. It includes the infrared lights and cooling fan which the strength is adjustable. This reduces the occurrence of ink set-off, even during high-speed printing. |

|

| Powerful Media transport system

Web tension is ensured by movable delivery/retraction bars that absorb tension differences and stabilize substrates so that high quality printing is made possible.

|

|

| Humanized design

When the printing stop, there is a function for the infrared heating and cooling fan stop working automatically, prevent the energy waste and danger caused by the high temperature.

|

|

|

Print technology |

Product Model |

TXR1802 |

TXR1804 |

|

Head |

Drop-on Demand Piezo Epson DX5 head | ||

|

Head quantity |

2 heads |

4 heads | |

|

Print mode |

Production |

4pass 28m2/h 720*720dpi |

4pass 56m2/h 720*720dpi |

|

Standard |

6pass 21m2/h 720*1080dpi |

6pass 42m2/h 720*1080dpi | |

|

High quality |

8pass 17m2/h 720*1440dpi |

8pass 34m2/h 720*1440dpi | |

|

Ink |

Type |

Reactive、Acid、dispersed ink optional | |

|

Supply system |

CISS(continuous ink supply system) | ||

|

Amount |

4*220ml cartridge, 8*1.8L ink tank | ||

|

Color variation |

4Color(C M Y K)、8color(C M Y K Lk R Bl Or) | ||

|

Media |

Type |

Cotton, Silk, Wool, Viscose, Tencel, Polyester, Nylon | |

|

Width |

Max. 1600~1800mm | ||

|

Thickness |

Max.8mm | ||

|

Weight |

Max. 80kgs | ||

|

Roll diameter |

Max. 40mm | ||

|

Media heater |

Infrared heating system equipped | ||

|

Media take-up device |

Auto Media feeding&take-up system equipped | ||

|

Interface |

USB 2.0 | ||

|

Software |

Texprint 、Photoprint、maintop | ||

|

Operating System |

Windows XP/ Windows7/Windows8 | ||

|

Operation environment |

Temperature:20~80℃ Humidity: 40%~60% | ||

|

Power specification |

AC22V, 50Hz | ||

|

Packing (dimension/weight) |

3.45*0.95*1.57m/400kgs |

3.45*0.95*1.57m/400kgs | |