|

|

|

|

Fast direct textile printing in high quality on up to 3.2m width

Super wide direct textile printing up to 3,200mm with TXR3202, using dye-sublimation ink, it is able to directly print on polyester fabric, applied to home textile(bed sheet, curtain, sofa cover, wall fabric), flags, water-based advertising(light box).

Other fabric with different ink is also available.

A speed of 28m²/h can be reached when printing at a resolution of 720*720dpi that is ideal printing model, perfect combination of printing quality and speed.

Specialized Textile printing software

Adopt specialized textile printing control system, the perfect wave curve can adapt well to temperature and humidity changes, realize stable printing without break line or head clog. Strong and big dot inkjet make sure that even high up the printhead for thick material, it can print very accurate and without any ink spray. It also highly improves the color gamut under same printing model compared with others.

Head height adjust

The print-head height adjust device can realize different thickness material print, it can adjust to more than 3.6mm (maximum 10mm) above, together with the new printing control system of accurate and powerful inkjet, it totally solve the normal problem of material scratching.

CISS (Continuous Ink Supply System)

The bulk ink supply system achieves stable unattended printing with 8pc big ink tanks (1.8L) and cartridges (220ml), thus in 4 color mode, a maximum of 4L per color is enabled for long continuous printing.

Operators can also refill the ink tanks even when the printer is at work.

Professional TEXPRINT RIP

Adopt professional TEXPRINT RIP software, achieve real textile 8 color. It has intelligent photocomposing and spot color function, with rich color gamut and perfect color performance. For mass textile production, the printed fabric will have exact same color. 4 or 6 color also avaliable to satisfy client’s demand for different printing quality and material feature.

|

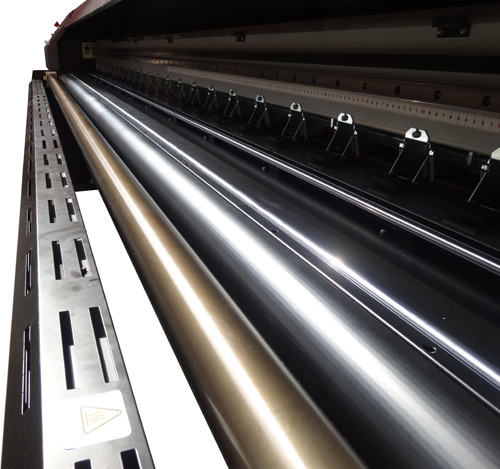

High precise roller for media smooth The printer use both front and back roller to smooth the media, the whole 3.2m roller keeps precise straightness without deviation, make sure the media will move evenly and directly forward.

|

|

|

Automatic feeding system The automatic feeding system is controlled by the electronic motor boards, with intelligent media sensor give signal, it can give very accurate media stepping without any overlap or gap, the balance rods generate constant tension, tight the media for smooth moving, so it won’t scratch the media even the printhead is adjusted low.

|

|

|

Unique pneumatic pressure type media roller The material roller use special pneumatic pressure control type, adjust the tension according to different kinds material, it can bear large 3.2m size heavy media without any physical winding or sharp change. The high accurate torque motor can also exactly adjust the rolling speed and strength according to the media type.

|

|

|

Front heating

There is front heating between printer platform and the smooth roller, it helps the printed fabric drying, avoid stain on the roller.

|

|

|

Fast speed with 4 printheads

The head configuration employs array of four staggered print heads, allowing for the fast speed printing of about 56 m2/h at 4pass, greatly improve the printing production.

|

|

Print technology |

Product Model |

TXR3202 |

TXR3204 |

|

Head |

Drop-on Demand Piezo Epson DX5 head | ||

|

Head quantity |

2 heads |

4 heads | |

|

Print mode |

Production |

4pass 28m2/h 720*720dpi |

4pass 56m2/h 720*720dpi |

|

Standard |

6pass 21m2/h 720*1080dpi |

6pass 42m2/h 720*1080dpi | |

|

High quality |

8pass 17m2/h 720*1440dpi |

8pass 34m2/h 720*1440dpi | |

|

Ink |

Type |

Reactive、Acid、dispersed ink optional | |

|

Supply system |

CISS | ||

|

Amount |

4*220ml cartridge, 8*1.8L ink tank | ||

|

Color variation |

4Color(C M Y K)、8color(C M Y K Lk R Bl Or) | ||

|

Media |

Type |

Cotton, Silk, Wool, Viscose, Tencel, Polyester, Nylon | |

|

Width |

Max. 3200mm | ||

|

Thickness |

Max.8mm | ||

|

Weight |

Max. 80kgs | ||

|

Roll diameter |

Max. 40mm | ||

|

Media heater |

Infrared heating system equipped | ||

|

Media take-up device |

Auto Media feeding&take-up system equipped | ||

|

Interface |

USB 2.0 | ||

|

Software |

Texprint、Photoprint、 maintop | ||

|

Operating System |

Windows XP/ Windows7/Windows8 | ||

|

Operation environment |

Temperature:20~80℃ Humidity: 40%~60% | ||

|

Power specification |

AC22V, 50Hz | ||

|

Packing (dimension L*W*H /weight) |

4.8*1.05*1.58m / 900kgs | ||